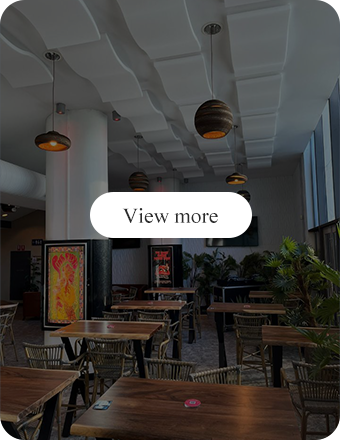

SELECT BY USAGE SCENARIO

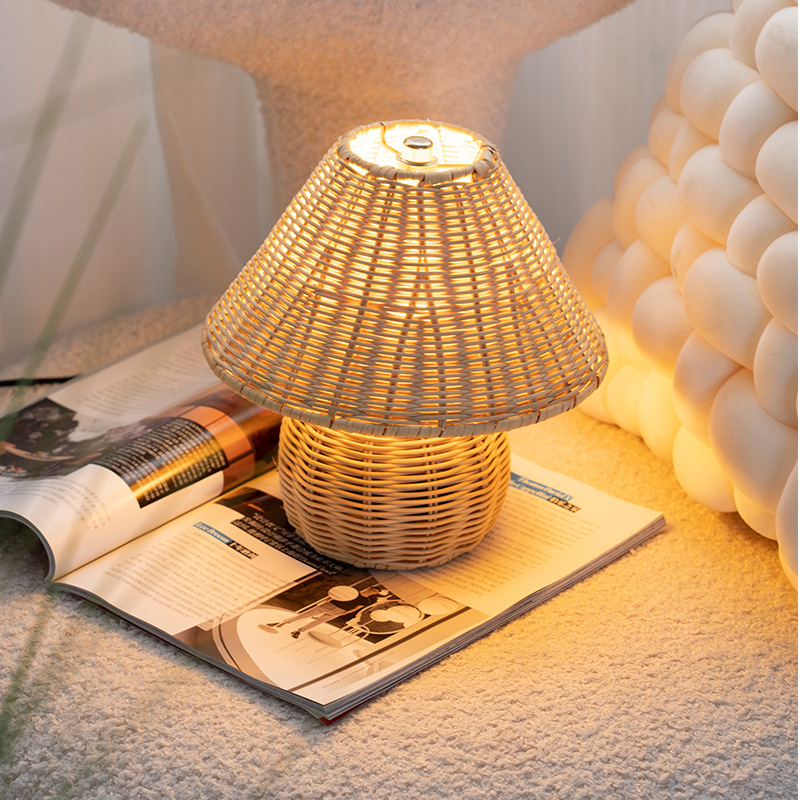

HOT SELLING PRODUCTS

PRODUCT ADVANTAGES

We are Danzi Lighting

Strict quality control

There are 12 quality inspection steps from raw materials to finished products (including integrating sphere light efficiency test and voltage aging test), and we promise to respond and resolve quality issues within 24 hours.

Flexible customization

We provide full-category customization (color/size/function) of chandeliers, wall lamps, atmosphere lamps, etc. to meet the scenario needs of restaurants, hotel projects, etc.

Modular design

The lamp structure can be disassembled and assembled, reducing the transportation loss rate by 30% and saving customers' storage and installation costs.

Precise light effect control

Equipped with 2 professional integrating sphere testers to ensure that the luminous flux, color temperature and color rendering index (CRI ≥ 80) of each lamp meet international standards

FACTORY VIDEO

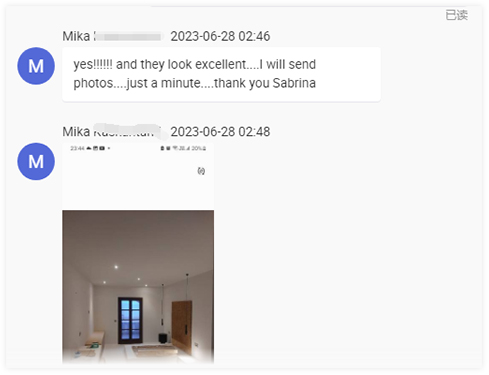

CUSTOMER PHOTOS

COMPANY HISTORY

PRODUCT ADVANTAGES

Capacity upgrade

Two assembly production lines have been built, equipped with 3 sets of automatic bending machines, integrating sphere testing instruments, etc., to achieve "small batch customization + fast delivery" capabilities, shortening the order cycle by 40%.

Capacity expansion

It has three assembly lines, equipped with five testing instruments, and has provided project engineering services to many hotels in the United States, which has been well received by guests.

Professional upgrade

The core team was expanded to 10 people, and a design and development department, a production control department, and a sales department were established to form a closed-loop capability of "demand-design

-delivery".

Company Founding

In 2018, the two founders founded Daner Lighting in Zhongshan, focusing on the field of customized lighting. With the mission of "delivering value with light", they are committed to providing personalized lighting solutions for hotels and home designs.

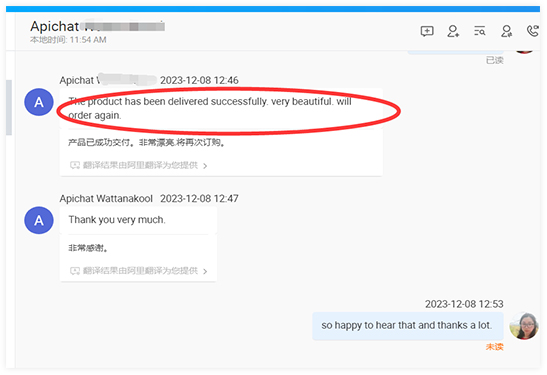

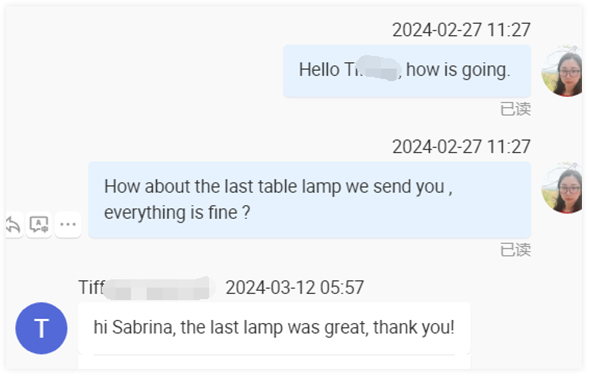

CUSTOMER FEEDBACK

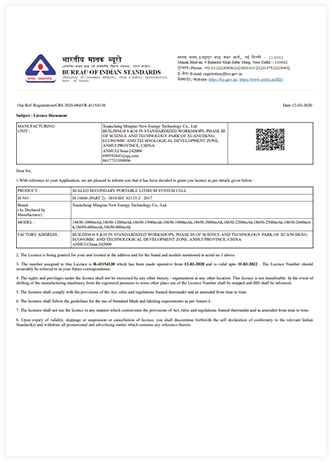

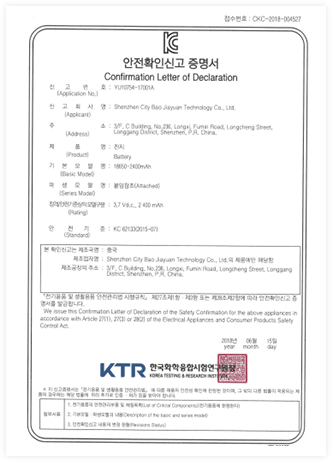

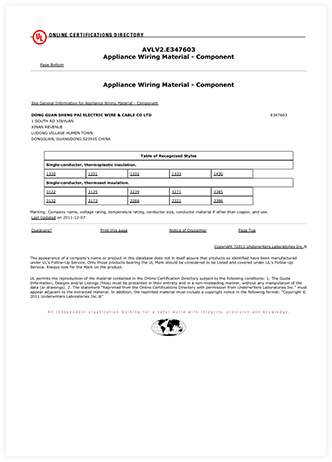

CERTIFICATE

PRODUCT CUSTOMIZATION

PROCESS

Demand communication

The customer has preliminary communication with the company's sales team to clarify the customization requirements, including lamp type, design style, size, material, color, function, etc.

Sample production

After the samples are completed, they will undergo strict quality tests (such as light efficiency test, durability test, etc.), and customers will inspect and accept the samples and provide feedback.

Mass production

After the sample is accepted, it enters the mass production stage. The production team strictly follows the design plan and quality standards for production.

Logistics delivery

Ship the packaged lighting products to the warehouse designated by the logistics company or directly load them onto trucks/ships to ensure a safe and efficient shipping process.

Solution Confirmation

The customer reviews the design plan and makes suggestions for revisions. The design team makes adjustments based on the feedback until the customer is satisfied.

Quality Inspection

After production is completed, a comprehensive quality inspection is carried out to ensure that each product meets the standards. After passing the inspection, it is packaged to ensure transportation safety.

After-sales service

Provide after-sales service support, including installation guidance, instructions for use and after-sales problem handling.

Sample testing

After the samples are completed, they will undergo strict quality tests (such as light efficiency test, durability test, etc.), and customers will inspect and accept the samples and provide feedback.

VIDEOS

YOUTUBE

NEWS

FAQ

CONTACT US

CORPORATE PARTNERS

Timelessdesign

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

_A1m2x0.png)

_sRv6l5.png)

_iGmzkc.png)

_fvzzNR.png)

.png)

_lutHu5.png)