The Role of Heat-Treated Bamboo in Sustainable Lighting Design

Discover how heat-treated bamboo enhances the quality, flexibility, and sustainability of handcrafted lighting.

来源:

|

作者:selina

|

Release time :2025-08-21

|

115 Views:

|

Share:

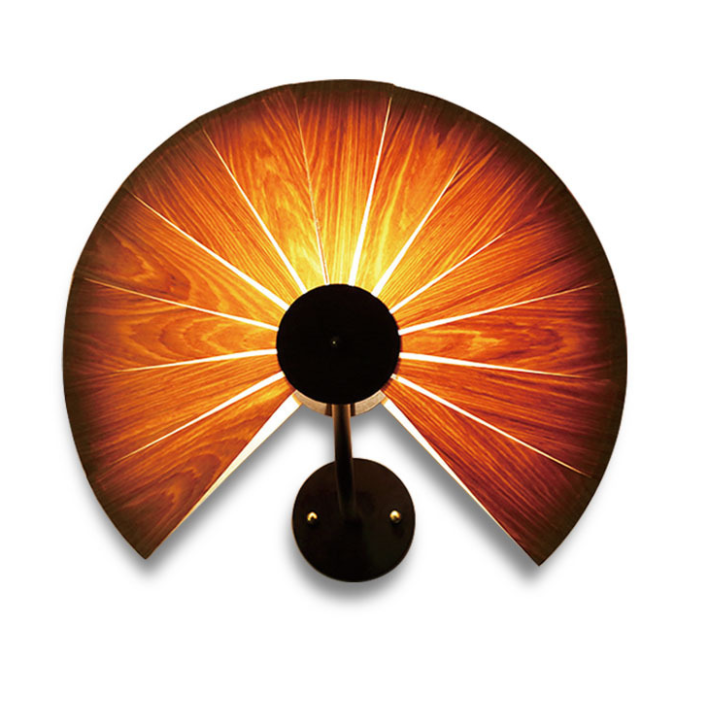

Crafting durable lighting from natural materials involves more than artistic weaving—it begins with precise heat treatment. Whether for a carbonized bamboo lamp or a handmade rattan bamboo light, baking plays a crucial role in longevity and quality.

1. Benefits of Heat-Treated Bamboo

Fire-hardened bamboo light fixtures resist cracking, perfect for humid environments.

The bamboo steaming process is a gentler alternative that allows artisans to mold and bend bamboo.

These methods prepare the material for intricate shapes in Japandi bamboo lighting and minimalist woven lamps.

By enhancing flexibility, this process supports the complexity of handcrafted home decor lighting.

2. Eco-Friendly Curing for Artisan Fixtures

Heat-conditioned rattan fixtures offer low-emission production methods.

Kiln-baked processes are common in creating eco‑friendly woven bamboo lamps.

Proper curing results in smooth, clean finishes for artisan bamboo light fixtures and decorative hand‑woven lights.

3. Applications in Interior Spaces

A dining room bamboo pendant with a textured finish becomes a focal point.

Cafe rattan lighting embraces handcraft and environmental values.

In bedrooms, a soft‑glow rattan light provides ambiance without harshness.

Kitchens benefit from the moisture-resistance of kitchen bamboo lamps.

READ MORE